ShipWeldFlow: Digital twins in ship production

12.1.2021 07:00:00 CET | Syddansk Universitet | Press release

By Jane Thoning Callesen

In the 1980s, Odense Steel Shipyard A/S collaborated with the local university SDU to build early robot solutions that could paint and weld. When the shipyard closed, the robot cluster slowly grew on Funen based on this know-how. And now, the latest technological advances in digitization and robotization will be brought back from the robot cluster to the maritime sector.

So says professor Christian Schlette from the Maersk Mc-Kinney Møller Institute at SDU. He is behind a new research project called ShipWeldFlow. With DKK 10 million in funding, the project will develop new digital tools to support the planning, operation, and automation of a ship's production.

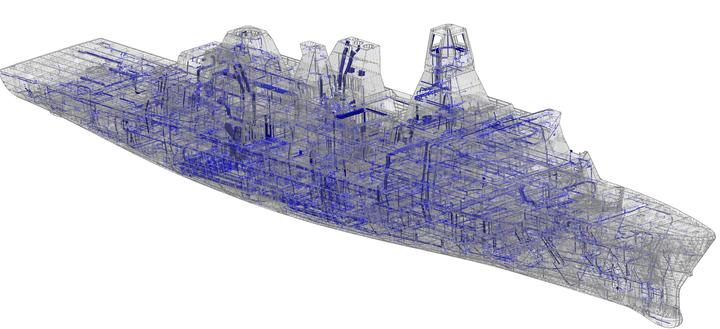

- Digital twins are a key part of Industry 4.0, but the technology is not yet widespread in the maritime sector, and we want to change that. By connecting physical robots with data and artificial intelligence, we can create a continuous digital analysis loop, where we optimize the design for production and the way the robots are weld, he says.

Local businesses on board

The project will be carried out with two local companies both with their roots from Odense Steel Shipyard: Odense Maritime Technology, which offers ship designs, shipyard designs, and advice on production automation, and Inrotech, which develops robotic welding solutions.

When a ship goes from design to production, there is a need for precise data on how the steel units should be welded and assembled. Today, most information is transmitted manually, which is time-consuming and cumbersome.

Based on digital twins of the production facilities, design data can be automatically processed by various simulation systems, thus creating a digital model of the overall production. This model provides a unique opportunity to analyze where improvement and intervention have the greatest effect. It helps to support optimal production and ensure that defects and material waste are avoided.

- The project will result in an unsurpassed planning tool that strengthens both the design side and the production. The digital model will bring us to the forefront in terms of ship production technology, which is incredibly important in the global competition, says Jens Viggers, Chief Process Officer at Odense Maritime Technology.

Robot-friendly design

At Inrotech, the new digital tools will be able to predict and measure how robots and sensors handle every specific steel unit at shipyards.

- It will make it easier for our customers to understand how much our robots can help in production, says Rasmus Faudel, Manager of Systems and Software at Inrotech.

- The introduction of welding robots at shipyards often requires that you make your ship design robot-friendly so that as much as possible can be welded automatically. Today, this optimization process often takes place when the robots are installed in production. With a digital twin, we can start this work much earlier in the process, and we will also be able to weld novel types of steel units using our robots.

Revolution for the maritime sector

In ship production, comprehensive digitization and robotization are still in their infancy, and so the parties envision great potential in the project.

- We expect that the use of digital twins will increase efficiency, reduce costs and waste, and improve welding performance, says Christian Schlette.

- The solutions we develop are based on the specific needs of the two companies. We look forward to sharing our results, and we hope that digitization and robotization will be extended to the entire maritime sector in Denmark later on.

FACTS

- The research project ShipWeldFlow runs until 1 March 2024. The goal is to digitize and optimize the way ships are designed and produced. The project has a budget of just over DKK 10 million, of which DKK 7.8 million stems from Innovation Fund Denmark. The focal point is digital twins and artificial intelligence.

- The ShipWeldFlow project is based on specific needs in the two companies, Odense Maritime Technology and Inrotech, which, like the Maersk Mc-Kinney Møller Institute, have roots back in the now-closed shipyard on Lindø. The new digital solutions will help maintain the companies' global competitiveness, support sustainable ship production, and healthy working environments in the maritime sector. The project supports the UN's goals 8, 9, and 12.

- Odense Steel Shipyard, often called Lindø Shipyard, was founded by shipowner A.P. Møller in 1917/1918. The shipyard helped set new standards for shipbuilding. It closed in 2012. The shipyard's collaboration with the University of Southern Denmark in the 1980s and 1990s formed the foundation for Danish robot adventures and made Funen a global center for robot companies.

Keywords

Contacts

Feel free to reach out to Communication Manager Jane Thoning Callesen for more information at +45 93507540 / jtca@mmmmi.sdu.dk

Images

About Syddansk Universitet

Subscribe to releases from Syddansk Universitet

Subscribe to all the latest releases from Syddansk Universitet by registering your e-mail address below. You can unsubscribe at any time.

Latest releases from Syddansk Universitet

Færre unge, flere ældre: På afgrundens rand?6.3.2026 13:41:43 CET | Pressemeddelelse

Syddansk Universitet sætter Danmarks demografiske dilemma under lup til et arrangement den 12. marts, hvor vi samler nogle af landets førende eksperter for at give historisk, økonomisk og politisk perspektiv på Danmarks demografiske fremtid.

Helene Skjøt-Arkil udnævnt til professor i ansvarlig brug af antibiotika i akutmodtagelsen ved SDU5.3.2026 13:00:00 CET | Pressemeddelelse

Professoratet skal styrke den patientnære forskning i diagnostik og målrettet antibiotikabehandling i akutmodtagelsen. Målet er hurtigere og mere præcis behandling, færre bivirkninger og mindre antibiotikaresistens

Stort internationalt projekt skal styrke kvinders mentale sundhed i overgangsalderen5.3.2026 10:26:18 CET | Pressemeddelelse

Forskere fra blandt andet Syddansk Universitet og Odense Universitetshospital har modtaget 36 millioner kroner fra Wellcome Trust til at undersøge, hvorfor nogle kvinder udvikler angst, depression eller bipolar lidelse i overgangsalderen, og om hormonbehandling kan forebygge alvorlig psykisk sygdom i denne livsfase.

Danskernes sundhed: Det går den forkerte vej på mange områder5.3.2026 06:00:00 CET | Pressemeddelelse

Klausuleret til den 5. marts 2026 kl. 06:00 Danskerne bliver ældre, men samtidig bliver de gode leveår færre. Den mentale trivsel er under pres, og andelen, der spiser usundt, er steget, og det gælder også andelen med langvarig sygdom. Samtidig er den sociale ulighed i sundhed markant. Det viser nye tal fra Den Nationale Sundhedsprofil 2025, som udkommer i dag.

Lene Juel Kjeldsen udnævnt til professor i hospitalsfarmaci ved SDU4.3.2026 14:08:32 CET | Pressemeddelelse

Professoratet skal styrke den praksisnære forskning i klinisk farmaci og bæredygtighed af lægemidler. Målet er at optimere den medicinske behandling og sikre mere ansvarlig anvendelse af lægemidler – til gavn for både patienter og samfund.

In our pressroom you can read all our latest releases, find our press contacts, images, documents and other relevant information about us.

Visit our pressroom