Danish robots assisting hard-pressed laboratory technicians with Covid-19 testing work

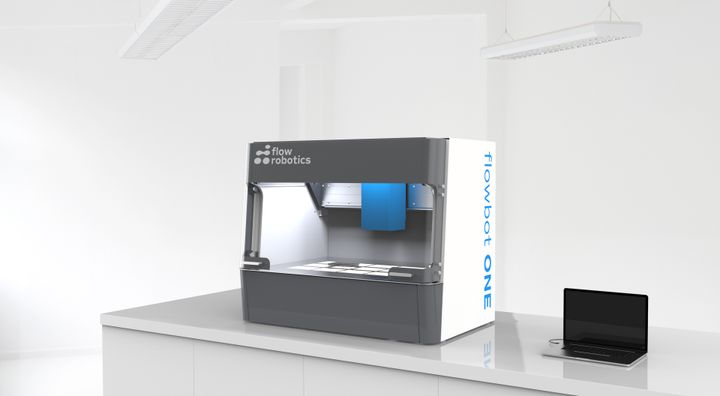

A unique liquid-handling robot from Denmark is now speeding up the great task of analysing Covid tests. Every day thousands of tests for Covid-19 are now being prepared for analysis by the sophisticated flowbot ONE from Flow Robotics. Robot technology minimises the risk of human error and contagion in the process, and it reduces the physically demanding pipetting tasks for laboratory personnel around the world.

Eight Danish hospitals have chosen the Danish invention, which is also being used by their partners DTU and Novo Nordisk. A German laboratory which had actually purchased the Danish robot to test for salmonella in food is now also using flowbot ONE when samples from German patients need to be analysed. Orders for the Danish liquid-handling robots have also come from Sweden, Poland, Russia, the Netherlands and Australia. Flow Robotics’ home in Denmark is not the only place where the health authorities have discovered the potential of automating part of the testing effort during the coronavirus pandemic.

The Danish manufacturer Flow Robotics can trump the other players on the international market in terms of usability, price and delivery time. In just three weeks, Flow Robotics can manufacture, supply and install 12 robots ready for use.

Consultant physician Jens Otto Jarløv, who works at Herlev Hospital in Denmark, is delighted to be able to automate processes in his laboratory:

“We are really pleased that Flow Robotics can deliver their robots so quickly. They are innovative and can automate just the things we need. We are very satisfied, and the co-operation has been very good,” he says.

The flowbot ONE robot enters the process right after inoculation, so to speak, where it automates the whole task of preparing samples for analysis, which is about mixing liquids and chemicals.

Since the beginning of May 2020, Flow Robotics has been helping to optimise the intensive work of analysing coronavirus samples.

“Although people’s eyes have been opened to the potential of our technology by the sad sight of a world ravaged by the pandemic, we are pleased to be able to make a difference for both patients and staff,” says the CEO of Flow Robotics, Annika Isaksson. In line with its global expansion, the company is scaling up robot production and recruiting new employees.

At Herlev Hospital, molecular biologist Martin Friis now works side by side with the Danish flowbot ONE robot:

“The robot pipettes the live virus, and it can pipette several samples at once, so we are now saving a lot of repetitive work and reducing the risk of accidents. We already keep ourselves safe, but it is still good for us to have less contact with the live virus thanks to the robot. The risk of pipetting errors is also eliminated as a result of automation because the robot follows a pattern and avoids mistakes. All in all, this lowers the stress level for us on many fronts, so we have less hassle in our work and minimise potential errors,” he says.

Keywords

Contacts

Interviewees:

Annika Isaksson, CEO of Flow Robotics: +45 5379 5202

Morten Rytter Sunesen, CCO of Flow Robotics: +45 4033 4205

Gorm Lisby, Consultant, Department of Clinical Microbiology 445, Hvidovre Hospital: +45 3862 2416

PR Consultant, Malene Grouleff: +45 28915809

Flow Robotics, Glentevej 70A, st tv, 2400 Copenhagen NV, Denmark

Images

Links

About Grouleff Communications

Subscribe to releases from Grouleff Communications

Subscribe to all the latest releases from Grouleff Communications by registering your e-mail address below. You can unsubscribe at any time.

Latest releases from Grouleff Communications

Robotter og andre nye teknologier kan give Djurslands mere end 75 fremstillingsvirksomheder nye superkræfter31.10.2022 14:02:32 CET | Pressemeddelelse

Det gælder om at digitalisere og automatisere sig ud af nogle af krisens mange udfordringer – men også at fokusere på opgradering af robot- og teknologikompetencer i produktionsvirksomhederne. Derfor inviterer organisationen Business Djursland til konkret erfaringsudveksling og ny inspiration med eventen Made by Djursland 2022.

Europe's Robot Capital Odense Presents 'Future of Robotics' at Capital Raising Summit in Munich16.6.2022 13:26:24 CEST | News

Robot investors from all over Europe can meet the continent's most promising robot startups when the event ‘Odense Investor Summit’ moves its matchmaking of capital seekers and investors to Munich for the first time. The summit takes place as part of the trade show Automatica with 45,000 attendees, featuring pitches from 15 companies with great growth potential at the show’s Startup Arena.

Europas robothovedstad Odense præsenterer ’Future of Robotics’ til kapitalrejsnings-event i München16.6.2022 12:54:43 CEST | Pressemeddelelse

Robotinvestorer fra hele Europa kan møde kontinentets allermest lovende robotstartups, når begivenheden Odense Investor Summit som noget helt nyt flytter sin matchmaking af kapitalsøgende og investorer til München. Det sker under robotmessen Automatica med 45.000 besøgende. På et podie i messens Startup Arena pitcher 15 selskaber med stort vækstpotentiale for kapitalstærke profiler.

Startups fra hele verden vil rejse 30 millioner i Europas robothovedstad Odense11.2.2022 14:50:49 CET | Pressemeddelelse

Hitraten er høj, når kapitalsøgende startups og risikovillige investorer mødes til Odense Investor Summit, der hver år foregår i Europas hurtigst voksende robotmiljø. Erfaringerne viser, at mere end halvdelen lykkes med at tiltrække investorkapital efter matchmaking-eventen. I år har 35 techselskaber fra Europa, Asien, USA og Afrika ansøgt om at præsentere ny teknologi til sundhed, landbrug, fremstillingsindustri og den maritime sektor for de 300 deltagende investorer. De 15 allermest lovende investeringsmuligheder får adgang til at pitche på podiet i byen Odense kendt som Cobot Capital.

PR-specialist og digitalt marketingbureau indgår samarbejde om robot- og automationsbranchen8.12.2021 07:00:00 CET | Nyhed

Robot- og automationsvirksomhederne stormer frem. En lang række firmaer får hjælp af PR-specialisten og influenceren, Malene Grouleff fra Grouleff Communications og marketingbureauet Conversio. Begge har stor indsigt i og erfaring med automatiseringsbranchen og er på få år blevet virksomhedernes foretrukne partnere. Nu indgår de et samarbejde om at booste robotindustriens synlighed og gennemslagskraft.