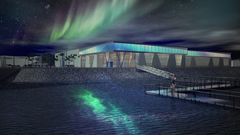

Danish business BILA to deliver enormous robot system for SalMar’s new InnovaNor facility in Norway

SalMar has announced the construction of a new factory, InnovaNor, in Lenvik Municipality in Norway, which will set new standards for innovative and efficient solutions in the salmon industry. Danish firm BILA will contribute by providing an innovative sorting and packing facility to handle thousands of tonnes of salmon.

SalMar’s new factory is expected to become one of the world's most efficient salmon factories, where the combination of maximum automation and innovation are the ingredients for success. BILA is a partner in the project and will provide an innovative, fully automated palletising solution that includes the processing and packing of salmon boxes. The groundbreaking solution was first implemented by BILA at a salmon industry customer’s facility in 2019, and it has now again been proven that the concept offers customers excellent opportunities. The factory is expected to be operational in mid-2021.

“We are proud that SalMar chose us as a partner for the new, ambitious InnovaNor factory. When it comes to productivity and efficiency, SalMar is the industry frontrunner – they bring everything to a new level and set the standard for the future of the salmon industry," says Jesper Højmark Pedersen, market unit manager

“Many suppliers showed interest in providing the palletising solution to InnovaNor. In the interaction phase leading up to the selection of suppliers, BILA showed a strong commitment both in terms of operational experience and concrete improvement measures for our facility at Frøya, InnovaMar. At the same time, BILA were very constructive in their contribution to devising a robust, flexible and not least dynamic solution that will always be able to meet SalMar’s requirements for the palletising plant," says Ole Meland, technical manager, SalMar AS.

BILA - 32 years of automation solutions

The BILA A/S group was founded in 1988 and provides the industry with production optimisation through automation solutions, typically using logistics solutions, industrial robots and cobots. The solutions cover everything from simple automation to optimising entire production lines. All competencies are gathered at BILA A/S and include consultancy, construction, development, implementation and subsequent servicing of robotic systems. The company has its own workshop where it develops and constructs special tools for the robotic facilities. BILA is a high-tech company employing more than 400 dedicated employees stationed at multiple locations in Denmark, as well as local offices in Sweden, Norway, Germany, the United States and England. Through the years, BILA has delivered more than 2,000 automation solutions to industrial companies in Europe and the United States.

Keywords

Contacts

Jesper Højmark PedersenMarket Unit Manager

Tel:+45 24493836jhp@bila.dkMalene GrouleffCEO

Tel:28915809malene@grouleff.itImages

Links

About Grouleff Communications

Subscribe to releases from Grouleff Communications

Subscribe to all the latest releases from Grouleff Communications by registering your e-mail address below. You can unsubscribe at any time.

Latest releases from Grouleff Communications

Robotter og andre nye teknologier kan give Djurslands mere end 75 fremstillingsvirksomheder nye superkræfter31.10.2022 14:02:32 CET | Pressemeddelelse

Det gælder om at digitalisere og automatisere sig ud af nogle af krisens mange udfordringer – men også at fokusere på opgradering af robot- og teknologikompetencer i produktionsvirksomhederne. Derfor inviterer organisationen Business Djursland til konkret erfaringsudveksling og ny inspiration med eventen Made by Djursland 2022.

Europe's Robot Capital Odense Presents 'Future of Robotics' at Capital Raising Summit in Munich16.6.2022 13:26:24 CEST | News

Robot investors from all over Europe can meet the continent's most promising robot startups when the event ‘Odense Investor Summit’ moves its matchmaking of capital seekers and investors to Munich for the first time. The summit takes place as part of the trade show Automatica with 45,000 attendees, featuring pitches from 15 companies with great growth potential at the show’s Startup Arena.

Europas robothovedstad Odense præsenterer ’Future of Robotics’ til kapitalrejsnings-event i München16.6.2022 12:54:43 CEST | Pressemeddelelse

Robotinvestorer fra hele Europa kan møde kontinentets allermest lovende robotstartups, når begivenheden Odense Investor Summit som noget helt nyt flytter sin matchmaking af kapitalsøgende og investorer til München. Det sker under robotmessen Automatica med 45.000 besøgende. På et podie i messens Startup Arena pitcher 15 selskaber med stort vækstpotentiale for kapitalstærke profiler.

Startups fra hele verden vil rejse 30 millioner i Europas robothovedstad Odense11.2.2022 14:50:49 CET | Pressemeddelelse

Hitraten er høj, når kapitalsøgende startups og risikovillige investorer mødes til Odense Investor Summit, der hver år foregår i Europas hurtigst voksende robotmiljø. Erfaringerne viser, at mere end halvdelen lykkes med at tiltrække investorkapital efter matchmaking-eventen. I år har 35 techselskaber fra Europa, Asien, USA og Afrika ansøgt om at præsentere ny teknologi til sundhed, landbrug, fremstillingsindustri og den maritime sektor for de 300 deltagende investorer. De 15 allermest lovende investeringsmuligheder får adgang til at pitche på podiet i byen Odense kendt som Cobot Capital.

PR-specialist og digitalt marketingbureau indgår samarbejde om robot- og automationsbranchen8.12.2021 07:00:00 CET | Nyhed

Robot- og automationsvirksomhederne stormer frem. En lang række firmaer får hjælp af PR-specialisten og influenceren, Malene Grouleff fra Grouleff Communications og marketingbureauet Conversio. Begge har stor indsigt i og erfaring med automatiseringsbranchen og er på få år blevet virksomhedernes foretrukne partnere. Nu indgår de et samarbejde om at booste robotindustriens synlighed og gennemslagskraft.