NIL Technology launches flat NIR metalenses ready for mass production

For more than a decade, camera lenses used in smartphones and other products have not seen revolutionary changes. Lenses are still made with multiple bulky refractive lenses or lens elements stacked on top of each other. NILT is on a mission to bring revolutionary changes to smartphone cameras by significantly reducing the size and complexity of these lens systems.

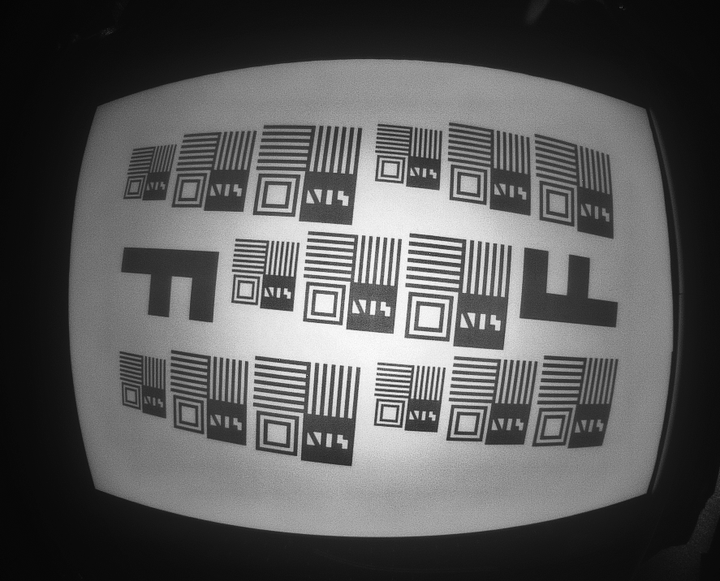

This first demonstration is a 940 nm near-infrared (NIR) wavelength imaging lens with a single metasurface, used for 3D sensing and face recognition in smartphones and driver-monitoring in automobiles.

The single metalens, as we will introduce as 1M, Meta Optical Element (MOE), is groundbreaking in its form, performance, compactness, and efficiency. It validates the uniqueness of MOEs over traditional refractive lenses.

- Compactness. MOEs are flatter, thinner, and lighter than refractive lenses, having a lens simplicity not demonstrated before.

- Superior. MOE lenses have significantly better imaging quality with a wide field of view, low F-number, high MTF, and high relative illumination, all at a low total track length.

- Cost-efficiency. Assembly costs and integration complexity will be lower.

- Robustness. Silicon on glass-substrate makes for strong, thermally stable lenses.

Design to delivery in only four weeks

NILT has more than 15 years of experience in high precision nanostructuring and is applying this to realize fast prototyping and mass production of MOEs. Prototyping is secured by high-quality Electron Beam Lithography (EBL) with a significantly quicker turnaround time than Deep UV Lithography (DUV). In addition, EBL gives ultra-high resolution and has a high degree of design freedom. Mass production is done by nanoimprint lithography (NIL), with no constraints on meta-atom geometries (size, shape, and location), ensuring best performing metalenses. In addition, nanoimprint lithography makes it possible for NILT to mass produce without relying on semiconductor geometrical limitations and processing capacity.

“Production of customized 1M MOEs is based on a combination of high expertise, and proven, validated, and reliable methodology,” says Theodor Nielsen, CEO & Founder in NIL Technology. “NILT is an established company with more than 1,500 purchase orders of experience. In addition, we have made customized prototypes for many years.”

NILT is designing, prototyping, assembling, and bringing up mass-production of metalenses. The entire process is done internally. As a result, NILT’s MOEs can be made in large quantities, with design to prototyping delivery in only four weeks and further redesign and turnaround in less than two weeks. Standard lenses with NILT designs are already shipped today.

Technical specs on the optical performance for the flat, multifunctional optics product platform for 3D sensing and LiDAR can be found on www.nilt.com/flat-nir-metalens-1m.

For inquiries, contact Brian Orr, VP Sales, at phone +1 408 497 4408.

For general information, contact Theodor Nielsen, CEO, at phone +45 3171 9036.

Keywords

Contacts

Sunniva MunkMarketing Manager

Tel:53771774sunni@nilt.comTheodor NielsenCEO & Founder

Tel:31719036theo@nilt.comImages

Links

About NIL Technology

About NILT

NIL Technology (NILT), founded in 2006, is an optical solutions company designing, developing, and manufacturing optical elements and components using high-precision nanoscale features. The company is backed by several industry-independent investors: Jolt Capital, NGP Capital, Swisscanto, Vaekstfonden, and the European Innovation Council (EIC). NILT creates competitive advantages with flat optics in optical applications for 3D sensing, consumer electronics, machine vision, autonomous vehicles, and VR/AR displays; all solutions made by diffractive optical elements (DOE) and metalenses/meta optical elements (MOE). NILT is based in Denmark and has offices in Switzerland, Sweden, and the US. Visit us at www.nilt.com.

Subscribe to releases from NIL Technology

Subscribe to all the latest releases from NIL Technology by registering your e-mail address below. You can unsubscribe at any time.

Latest releases from NIL Technology

Metalens breakthrough with extremely high efficiency demonstrated by NIL Technology12.10.2021 09:13:46 CEST | Press release

Copenhagen, Denmark, 12 October 2021. NIL Technology (NILT), a leader in modern optical solutions, announces a breakthrough performance in metalens optics. NILT has designed, built, and characterized multiple meta optical element (MOE) lenses with 94% absolute efficiency.

NIL Technology introduces flat, multifunctional optics platform for 3D sensing and LiDAR applications13.7.2021 09:39:49 CEST | Press release

Copenhagen, Denmark, 13 July 2021. NIL Technology (NILT), a leader in advanced optical solutions, is launching its highly advanced flat optics technology platform for near-infrared (NIR) used in 3D sensing and LiDAR. The technology will become a gamechanger for smartphones, automotive, and other applications, due to its multi-functionality, compactness, and unprecedented optical performance.

NIL Technology sikrer 200 mio. kr. finansiering: Dansk nanoteknologi skal sælges til verdens største smartphone brands24.2.2021 08:15:00 CET | Pressemeddelelse

NIL Technology, er en dansk nanoteknologivirksomhed, der står foran et internationalt gennembrud. Ambitionen? Virksomhedens nanoteknologi vil være at finde i stort set alle de førende brands af smartphones inden for et par år. Med en 200 mio. kr. finansiering i ryggen fra bl.a. Jolt Capital, Vækstfonden, NGP Capital og EIC Fund, sætter NIL Technology fart på det, der skal være et internationalt gennembrud af de helt store.