Ørsted successfully pilots new technology that further optimises offshore wind monopile installation

12.7.2024 09:00:00 CEST | Ørsted A/S | Press release

Building on existing marine life protections, Ørsted has developed a new, lower-noise installation method that could potentially revolutionise the way offshore wind foundations are installed. The groundbreaking new technology has been successfully tested in Germany, proving that this innovative approach can dramatically reduce noise levels during foundation installations, strengthening existing protections to marine life and potentially paving the way for the next generation of monopile foundations.

This leading-edge technology represents one of the greatest advancements yet in offshore wind foundation installation methodology. It is also the latest example of how Ørsted, the global offshore wind leader, continues to harness innovation that supports biodiversity, protects the environment, and creates the green energy systems of tomorrow.

Ørsted is already implementing a range of effective protective measures during offshore wind farm construction, including limiting the duration, intensity, or extent of certain offshore construction activities. Examples of these mitigating measures include the deployment of bubble curtains or other noise barriers during traditional installation. The new installation method allows Ørsted to further reduce the potential impact from construction activities on the marine environment and build in a more cost-effective way.

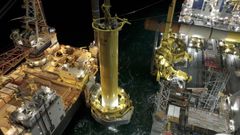

At the new German offshore wind farm Gode Wind 3, Ørsted has successfully tested an innovative installation method on three monopile foundations. The noise mitigation method involves a patented jetting technology attached to the monopile, which lowers the resistance of the surrounding sandy soil, effectively allowing the foundation to sink into the seabed – completely replacing conventional installation methods such as pile driving. The implementation of the new installation technology has resulted in a substantial decrease in underwater noise levels: With a reduction of 34 decibels relative to the most commonly used installation method, and without additional mitigation, noise levels were reduced by over 99 % to a level just marginally above the ambient noise found in the German Bight in the North Sea.

Beyond the noise reduction, this new technology is a step change in offshore wind monopile installation that, once adopted at scale, can provide for more efficient and cost-effective installations of offshore wind foundations. 11 MW wind turbines have already been installed on top of the foundations, and Gode Wind 3 is expected to start commercial operation later this year.

Patrick Harnett, Executive Vice President and Chief Operating Officer at Ørsted, said: “Ørsted has been at the forefront of offshore wind innovation and marine protections for 30 years, and we continue to push the envelope on new innovative solutions. This new technology is a potential game changer for how we build offshore wind. Once industrialised, it could not only be cheaper, faster, and far quieter – without additional mitigation – than any other monopile installation technology, it also has the potential to make next-generation foundations lighter as they won’t need to be designed for conventional installation process.”

This is the first time a jetting technology has been used to install full-size monopile foundations, making the tests a milestone for the entire industry. Ørsted carried out the installation together with Jan De Nul Group and their installation vessel Les Alizés as well as contractor Aarsleff. Ørsted has been developing the technology over the past years and is now looking into how to introduce the technology into the future pipeline, which includes assessing the feasibility of the method on more complex ground conditions than the pure sand conditions found at the Gode Wind 3 site. Further regulatory approvals will also be needed before the technology can be implemented in other markets globally.

At the cutting edge of offshore wind innovation

The new technology is a testimony to Ørsted’s approach to innovation, which has been core to Ørsted’s business from the very beginning, helping to take offshore wind power from a demonstration concept to a large-scale energy technology.

Advances in technology have already brought down the costs of renewable energy, making it cost-competitive with fossil fuels, and Ørsted believes it can continue to harness cutting-edge technology to make green energy more affordable, reliable, efficient, and sustainable across the value chain. Recently, Ørsted has deployed an autonomous vessel for offshore surveying, and the company is testing the use of large drones to transport cargo to offshore wind turbines.

Ørsted has in-house R&D capabilities led by a team with deep science and engineering expertise, overseeing 300+ different projects, and the company has partnered with over 50 universities and research institutes, helping to bring the best ideas from the lab to the field.

For successful implementation at Gode Wind 3, Ørsted will receive subsidies from the German Federal Network Agency (BNetzA) under the Offshore Wind Energy Act, intended to drive innovation in the offshore wind build-out.

For further information, please contact:

Ørsted Global Media Relations

Kathrine Ejlskov

+45 99 55 10 23

katej@orsted.com

Ørsted Germany Media Relations

Steffen Kück

+49 173 151 9276

steku@orsted.com

About Ørsted

The Ørsted vision is a world that runs entirely on green energy. Ørsted develops, constructs, and operates offshore and onshore wind farms, solar farms, energy storage facilities, renewable hydrogen and green fuels facilities, and bioenergy plants. Ørsted is recognised on the CDP Climate Change A List as a global leader on climate action and was the first energy company in the world to have its science-based net-zero emissions target validated by the Science Based Targets initiative (SBTi). Headquartered in Denmark, Ørsted employs approx. 8,900 people. Ørsted's shares are listed on Nasdaq Copenhagen (Orsted). In 2023, the group's revenue was DKK 79.3 billion (EUR 10.6 billion). Visit orsted.com or follow us on Facebook, LinkedIn, Instagram, and X.

Images

Documents

Alternative languages

Subscribe to releases from Ørsted A/S

Subscribe to all the latest releases from Ørsted A/S by registering your e-mail address below. You can unsubscribe at any time.

Latest releases from Ørsted A/S

Ørsted udpeger Simon Ashley til ny HR-koncerndirektør, da Henriette Fenger Ellekrog afslutter sin direktionskarriere28.1.2026 08:04:00 CET | Pressemeddelelse

Ørsted har udpeget Simon Ashley til ny HR-koncerndirektør og medlem af koncernledelsen med virkning fra 1. august 2026. Udpegelsen sker som led i et planlagt lederskifte, da Henriette Fenger Ellekrog, nuværende HR-koncerndirektør, har valgt at afslutte sin direktionskarriere.

Havvindaftale er et afgørende skridt henimod at forsyne Europa med vedvarende, sikker og konkurrencedygtig elektricitet26.1.2026 12:30:10 CET | Pressemeddelelse

Den fælles investeringsaftale for havvind i Nordsøregionen er et afgørende skridt henimod at forsyne Europa med vedvarende, sikker og konkurrencedygtig elektricitet. Med mere forudsigelighed i investeringerne, en investeringsramme, hvor risiciene er blevet reduceret, og en koordineret udbygningsplan på op til 15 GW om året i Europa arbejder Ørsted og havvindindustrien målrettet på at sænke prisen på energi fra havvind med 30 % inden udgangen af 2040.

Ørsted ranked as a global sustainability leader by Corporate Knights21.1.2026 06:02:00 CET | Press release

Ørsted takes ninth place in this year’s Corporate Knights Global 100, which ranks the most sustainable companies in the world based on an assessment of the companies’ sustainability performance. This is the ninth year in a row that Ørsted is included on the Global 100 list of the most sustainable companies in the world. Ingrid Reumert, Senior Vice President for Global Stakeholder Relations at Ørsted, says: “We’re pleased to be recognised as a global sustainability leader by Corporate Knights and to be ranked among the top ten most sustainable companies in the world again this year. Our ambition is to bring more green electrons to the grid in a sustainable manner, and we’re fully committed to helping communities, companies, and countries decarbonise through green, secure, and affordable energy.” The main drivers behind Ørsted’s continued high ranking are its high shares of sustainable revenue (91 % in 2024) and sustainable investments (99 % in 2024). In 2025, Ørsted achieved its industr

Ørsted kåret som en af verdens mest bæredygtige virksomheder af Corporate Knights21.1.2026 06:02:00 CET | Pressemeddelelse

Ørsted indtager en niendeplads i dette års udgave af Corporate Knights' Global 100, der rangerer de mest bæredygtige virksomheder i verden baseret på en vurdering af virksomhedernes indsats inden for bæredygtighed. Det er niende år i træk, at Ørsted er blandt de 100 mest bæredygtige virksomheder i verden. Ingrid Reumert, Senior Vice President og direktør for kommunikation og bæredygtighed i Ørsted, siger: "Vi er glade for at blive anerkendt af Corporate Knights som et af verdens førende selskaber inden for bæredygtighed og for at blive kåret som en af de ti mest bæredygtige virksomheder i verden igen i år. Det er vores ambition at levere flere grønne elektroner til elnettet på en bæredygtig måde, og vi arbejder hårdt på at hjælpe lokalsamfund, virksomheder og lande med at nedbringe deres CO2-udledninger ved hjælp af grøn, sikker og omkostningseffektiv energi." Hovedårsagen til Ørsteds fortsat høje placering i Global 100-indekset er, at virksomheden genererer en stor del af sin omsætnin

All wind turbines installed at Ørsted’s 920 MW Greater Changhua 2b and 4 offshore wind farms in Taiwan20.1.2026 09:00:00 CET | Press release

The installation of the last wind turbine at the 920 MW Greater Changhua 2b and 4 offshore wind farms in Taiwan was completed last week, marking a successful conclusion of the wind turbine build-out and a landmark milestone for the offshore wind industry in the Asia-Pacific region. Located 35–60 kilometres off the coast of Changhua County, Taiwan, Greater Changhua 2b and 4 comprises 66 state-of-the-art 14 MW SG 14-236 wind turbines. Offshore construction of the 920 MW project began in February 2025, with wind turbine installation commencing in April last year, executed by wind turbine supplier Siemens Gamesa using Cadeler’s newly built installation vessel, Wind Maker. The Greater Changhua 2b and 4 offshore wind farms are the first of their kind in the Asia-Pacific region to supply renewable electricity to Ørsted’s corporate customer on the project under a corporate power purchase agreement signed in 2020. Since achieving first power in July 2025, the project has been delivering renewab

In our pressroom you can read all our latest releases, find our press contacts, images, documents and other relevant information about us.

Visit our pressroom